Monica Manolas

President, Ash Grove South, a CRH Company

In October, the Portland Cement Association released its Roadmap to Carbon Neutrality, which outlines an approach that leverages the entire value chain to lower emissions. The first link in that value chain is clinker; clinker is a binding agent that is the precursor to cement, the key ingredient in concrete.

While most Americans will never see clinker unless they visit a cement plant as it is an intermediate product, it is essential to cement manufacturing. The key chemical reaction to produce clinker is responsible for more than 60% of CO2 emissions from cement production. There is currently no way around this “chemical fact of life” and no viable alternative to clinker that can be produced at the scale society needs. There are, however, opportunities to optimize energy use, shift away from traditional fossil fuels, and utilize carbon capture technology to avoid emissions.

Decarbonated raw materials

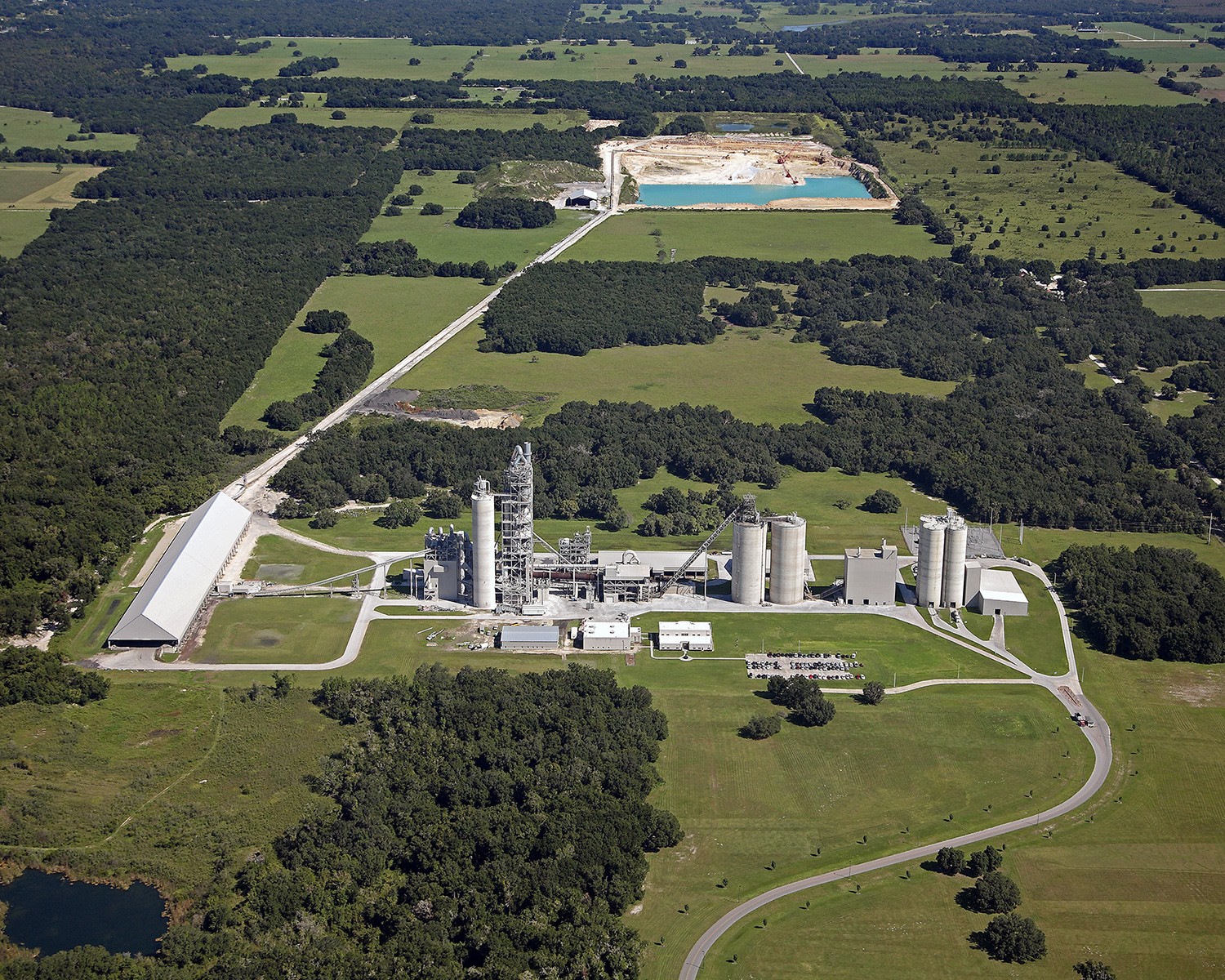

Clinker starts with quarried materials like limestone, clay, shale, and sand that must be heated and processed. To reduce these emissions, manufacturers can use decarbonated raw materials that have already been processed to no longer contain CO2. These materials often end up in landfills, so in addition to avoiding processing emissions, these materials are also brought into the circular economy.

Today, these materials represent less than 5% of cement manufacturers’ raw material input; with the right policies, that could be doubled. By 2050, the industry is targeting replacing virgin raw materials with at least 10% decarbonated raw materials.

Fuel switching

Clinker production requires material temperatures of nearly 3,000 degrees Fahrenheit, and those temperatures can only be achieved with combustion. The industry’s current fuel mix includes 60% coal and petcoke, with alternative fuels making up only a fraction of the current fuel mix. These alternative fuels range from cellulosic biomass to non-recycled plastics, residuals from paper and cardboard recycling, and agricultural wastes – all opportunities to give spent materials a second, productive life.

Current regulations limit the use of non-hazardous secondary materials, even when those materials can be beneficially used in lieu of fossil fuels. Cement plants are already equipped to use alternative fuel materials. With the right policies and regulations, alternative fuels could make up 50% of the industry’s fuel mix.

The industry is also advocating for the use of “transition” fuels, like natural gas, while renewable fuel sources become available at scale. Displacing traditional fossil fuels with natural gas in the near-term cuts CO2 combustion emissions by 24%. With the right infrastructure investment, cement producers can switch to renewable sources of electricity like wind and solar to eliminate CO2 created from fossil fueled power plants.

Improving energy efficiency

Cement manufacturing is already one of the most energy efficient industrial processes – with today’s technologies operating above 80% thermal efficiency. Producers are constantly looking for new opportunities to improve, and many cement plants are U.S. EPA ENERGY STAR certified for performing in the top quartile.

Using modernizations, upgrades, machine learning, and artificial intelligence the goal is to reduce the 3.84 MM BTU of energy it takes to produce one metric ton of clinker by more than 25%.

Carbon capture

In the long term, carbon capture, utilization and storage (CCUS) is a critical part of cutting emissions in cement production. CCUS effectively captures CO2 to either be used to produce new materials or be safely and permanently sequestered. While at-scale CCUS will take significant research and development efforts, the industry continues to advocate for the right policies and investments to make carbon capture an integral part of any cement plant.

Clinker is the first step in a value chain that results in the concrete infrastructure we experience every day. Working to implement actions and policies and research and investment that bring down emissions at the cement plant is crucial for the industry to reach carbon neutrality and be a part of creating a more sustainable built environment.